3D Printing - Getting started with Ender 3

| Attachment | Size |

|---|---|

| tinkercad-keyboard-shortcuts.pdf | 1.06 MB |

Pick a entry level printer: Creality Ender 3X 3D Printer - includes glass print bed

Creality Ender 3 Assembly and Quick Start Guide

Order PLA Black: HATCHBOX PLA 3D Printer Filament, Dimensional Accuracy +/- 0.03 mm, 1 kg Spool, 1.75 mm

Download from MyMiniFactory:

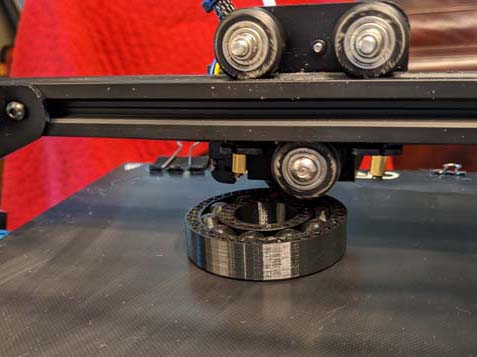

QuickLevel Printer Bed Calibration Tool

XYZ 20mm 3D printer Calibration Cube

#3DBenchy - The jolly 3D printing torture-test

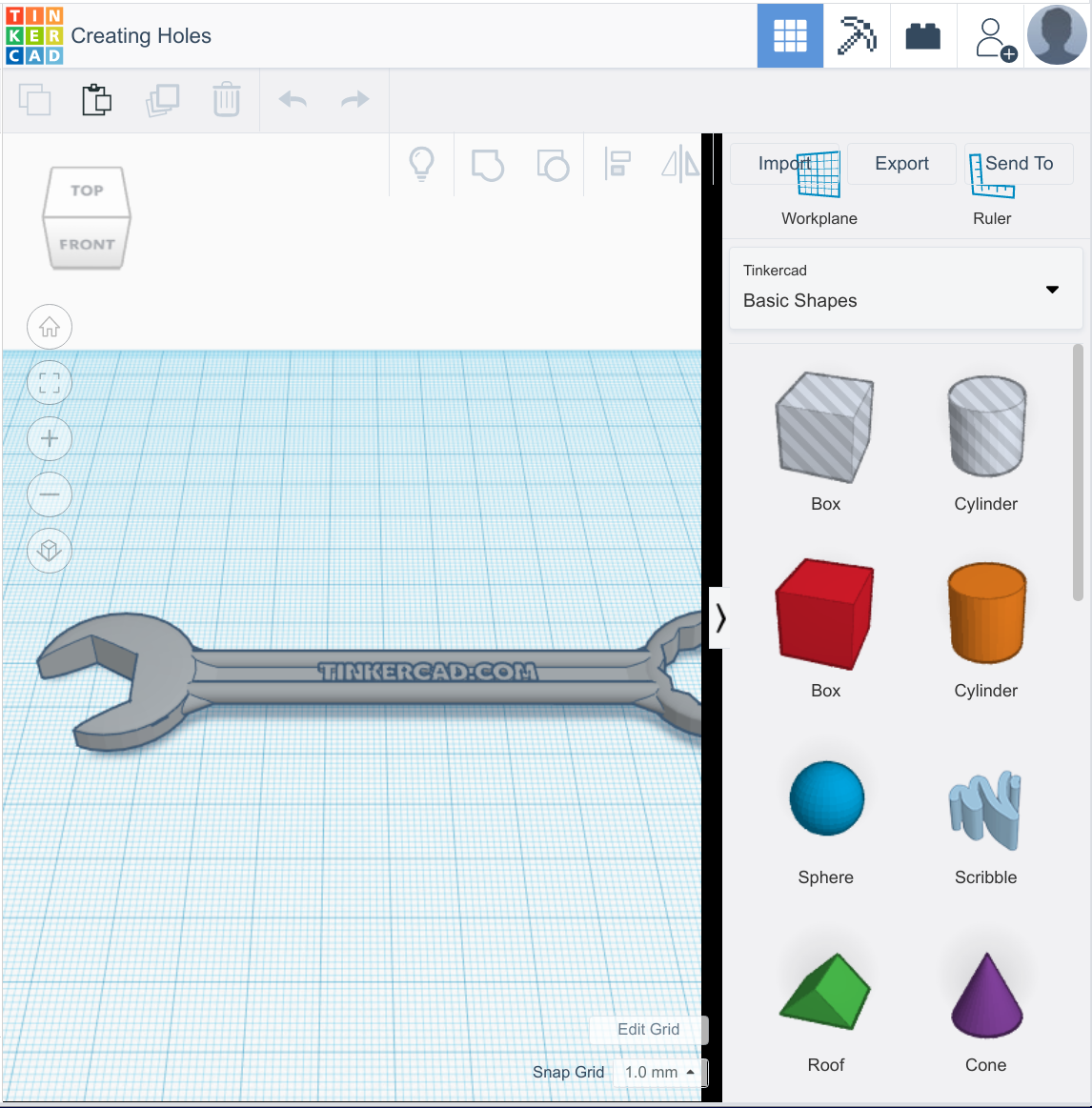

Try TinkerCAD Drawing web site, Keyboard short cuts

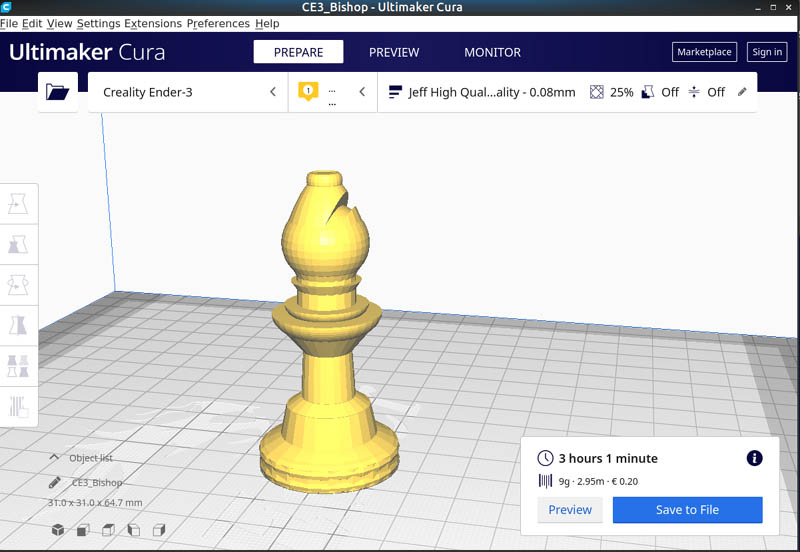

Slicing the .stl file for the printer

- Install Cura Slice software on Ubuntu: Ultimaker_Cura-4.12.1.AppImage Make file executable then run

- Cura Slicer 4.12.1 Features, Tips and Tricks for 3D Printing

- Video explaining every Cura setting, useful for high quality or miniature prints.

- Cura Supports, adding removing

Printing replacement chess pieces

How to get prints to stick to the plate (I was ready to return my printer)

At first I found I could clean the plate with rubbing alcohol and with a new glass plate most things would stick. Sometimes I also needed to add a brim in Cura to the slice if there was not  much surface area on the plate. I asked my friend for advice and he said he usually uses Elmers Purple Glue stick. I found that works well. I can sometimes get a couple of prints on the same glue stick application. Warning: don't try to use a cotton ball with alcohol to clean up the glue stick on the plate. It results in the cotton fibers stuck to the glue. I just use warm to wet a wash rag and clean off all the glue. When dry and the plate is preheated I just put on a fresh coat of glue. Seems to work very well.

much surface area on the plate. I asked my friend for advice and he said he usually uses Elmers Purple Glue stick. I found that works well. I can sometimes get a couple of prints on the same glue stick application. Warning: don't try to use a cotton ball with alcohol to clean up the glue stick on the plate. It results in the cotton fibers stuck to the glue. I just use warm to wet a wash rag and clean off all the glue. When dry and the plate is preheated I just put on a fresh coat of glue. Seems to work very well.

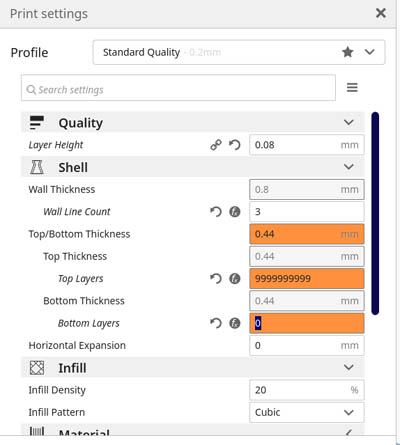

High resolution minis, trick to print every layer as top layer

- 100% infill in Cura

- Very small layer height 0.08

- Go Slow

- Plenty of supports choose zig zag

Note: I have had much better success when I just print in standard quality. Printing in these high resolutions is tricky and often the prints don't adhere to the plate.

Pick a entry level printer: Creality Ender 3X 3D Printer

Is the Ender pro worth it? Ender 3 PRO vs Ender 3 - Detail comparison

Order PLA Black: HATCHBOX PLA 3D Printer Filament, Dimensional Accuracy +/- 0.03 mm, 1 kg Spool, 1.75 mm

Creality Ender 3 Upgrades:

Heat-bed insulation -- https://goo.gl/ubu8MJ C

reality spare nozzle -- https://goo.gl/GV3HeG

Printable Creality Ender 3 Upgrades:

Fan guard -- https://www.thingiverse.com/

Fan guard -- https://www.thingiverse.com/thing:293... - LCD cover -- https://www.thingiverse.com/

thing:298... - Feet(damping) -- https://www.thingiverse.com/

thing:291... - Filament guide -- https://www.thingiverse.com/

thing:289...

3D printer calibration

More to come on the site in future: https://teachingtechyt.github.io/ Website source and place to lodge bugs/feature requests: https://github.com/teachingtechYT/tea...

Timestamps:

0:00 Introduction 0:17 Overview 2:07 Structure and warnings 2:46 Frame check 3:35 PID autotune 4:36 Baseline print 7:02 E-steps 8:23 Slicer flow rate 9:51 Stepper motor driver current 11:09 Retraction 13:25 Temperature 14:32 Acceleration and jerk/junction deviation 17:18 Linear advance 18:28 Summary

How to print flexible prints

PLA and ABS are not flexixible, Nylon is a little flexible and TCP is very flexible

I decided on PCTPE Nylon as a good middle ground not too hard to print, some flexibility.

Dealing with moisture in filaments

I found that a 2 gallon bucket fits 3 spools of filament and I just throw in some Silica Gel Packets with them to absorb any moisture. The Gel packets can be can be recharged in the microwave.

I found that a 2 gallon bucket fits 3 spools of filament and I just throw in some Silica Gel Packets with them to absorb any moisture. The Gel packets can be can be recharged in the microwave.

Nylon Filament

- Max Ender 3 Tip can go is 250 C, better printing at 260 C for Nylon

- Bed at 100 C

- Gluestick on Glass for the bed

- Turn off the layer cooling fan

- Retract distance 3 mm

- Slow down print speed

Upgrades for Nylon

- Micro Swiss All Metal Hotend Kit for Creality. - Required (installation video)

- Direct Drive Mod - needed for TPU probably not needed for Nylon

- Box enclosure or print in corner out of any drafts - Helps keep temperature constant

- Insulation on bottom of print bed - raise max temp of print bed a little

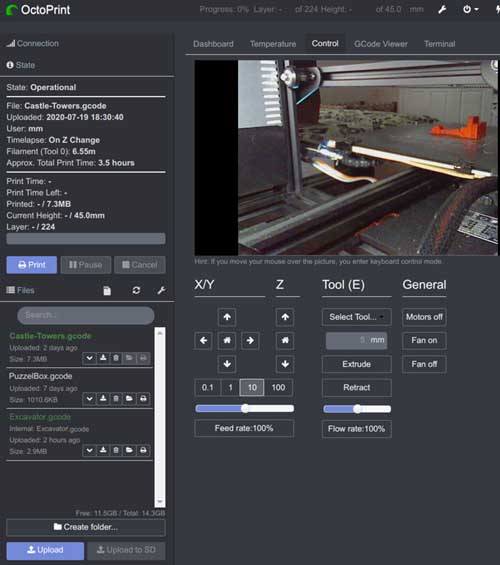

Octoprint with Raspberry Pi 4 b

- OctoPi version of Octoprint for Raspberry Pi

- Case for Pi 4b with rails to connect to Ender printer

- Octoprint Plugins

Show Raspberry Pi GPU and ARM CPU temperature

Monitory CPU speed and temp Sample output

$ ./temp.sh Date Time GPU-C GPU-F CPU-C CPU-F CPU Core Vcore Jul 29 18:46 80.0'C 176.0'F 80.8'C 177.4'F 1500MHz 500MHz 0.8455V Jul 29 18:46 79.0'C 174.2'F 79.8'C 175.6'F 1500MHz 500MHz 0.8455V Jul 29 18:47 81.0'C 177.8'F 81.8'C 179.2'F 1500MHz 500MHz 0.8455V

Edit a file temp.sh and add the following:

#!/bin/bash

Counter=20

DisplayHeader="Date Time GPU-C GPU-F CPU-C CPU-F CPU Core Vcore"

while true ; do

let ++Counter

if [ ${Counter} -eq 21 ]; then

echo -e "${DisplayHeader}"

Counter=0

fi

Clockspeed=$(vcgencmd measure_clock arm | awk -F"=" '{printf ("%0.0f",$2/1000000); }' )

Corespeed=$(vcgencmd measure_clock core | awk -F"=" '{printf ("%0.0f",$2/1000000); }' )

CoreVolt=$(vcgencmd measure_volts | cut -f2 -d= | sed 's/000//')

gpu=$(/opt/vc/bin/vcgencmd measure_temp | awk -F "[=\']" '{print $2}')

cpu=$(</sys/class/thermal/thermal_zone0/temp)

cpu=$(echo "$cpu / 100 * 0.1" | bc)

cpuf=$(echo "(1.8 * $cpu) + 32" |bc)

gpuf=$(echo "(1.8 * $gpu) + 32" |bc)

echo -e "$(date '+%b %d %H:%M') ${gpu}'C ${gpuf}'F ${cpu}'C ${cpuf}'F $(printf '%4s' ${Clockspeed})MHz $(printf '%4s' ${Corespeed})MHz ${CoreVolt}"

sleep 10

done